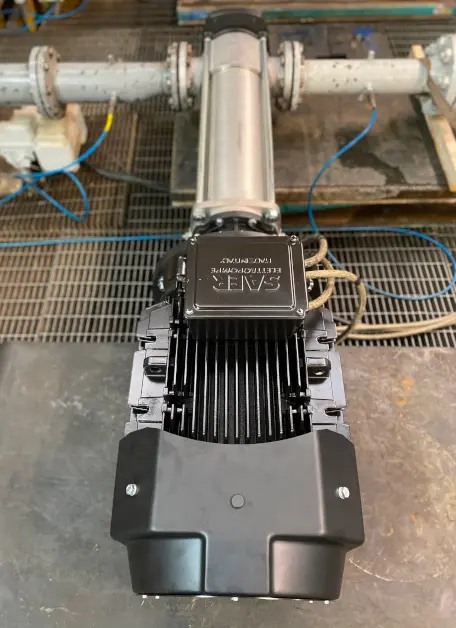

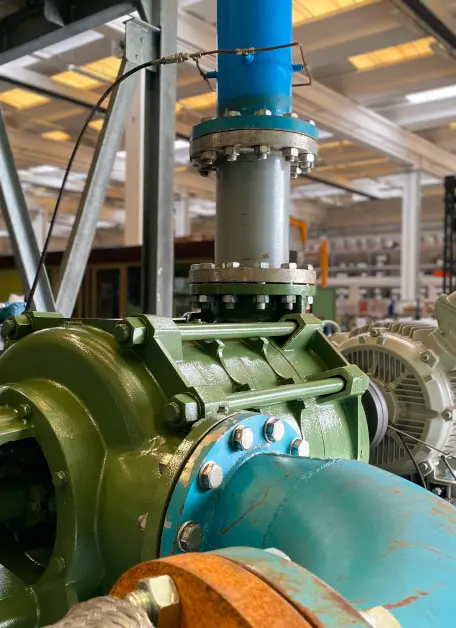

Testing laboratories to determine the quality and characteristics of electric motors and pumps, from the testing of the prototypes to the final production check before they are put on sale.

SAER's testing rooms are highly specialised, technologically advanced environments which are designed to conduct accurate and reliable tests. Designed and organised to simulate the actual operating conditions of the pumps and motors, even under high-stress conditions, the testing rooms allow SAER's engineers and technicians to evaluate the performance, efficiency and reliability of the products.

TESTED AND CERTIFIED

QUALITY

PRODUCTS

TESTED

- Surface pumps and motors

- Submersible pumps and motors

- Pumps for waste water

- Solar pumps

- Electrical switchboards and inverters

TESTING

CAPACITIES

- Maximum flow rate 4,500 m³/h

- Maximum power 1,500 kW

- Maximum pressure 100 bar

- Maximum supply voltage

- Low voltage: 1000 V

- High voltage: 11 kV

- Supply frequency 50 / 60 Hz

- VFDs up to 1,500 kW

- Motor torque up to 5,000 Nm

POSSIBLE

TESTS

SAER

ALL TESTS

TESTS ON MOTORS - Standard: EN 60034

ATTENDED TEST - On request, the tests can be performed in the presence of bodies accredited for the certification tests, or can be attended by the customer

MATERIALS ANALYSIS - Chemical analysis of the composition of the metals can also be performed using an optical emission spectrometer or X-ray quantometer, with the certificate 3.1 issued in accordance with EN10204

SAER'S TESTS

HYDRAULIC

TESTS

EN ISO 9906:2012

FLOW RATE-HEAD CURVE

POWER

(pump, motor, complete unit)

EFFICIENCY

(pump, motor, complete unit)

NPSHR

ELECTRICAL PARAMETERS

(voltage, current, frequency, cosφ)

ROTATION SPEED

TESTS ON

MOTORS

EN 60034

GENERAL PERFORMANCE

(power, efficiency, cosφ, rpm, torque, current)

POWER

EFFICIENCY

NPSHR

ELECTRICAL PARAMETERS

ROTATION SPEED

OTHER

TESTS

VARIABLE SPEED TESTS

HYDROSTATIC TESTING(up to 100 bar)

ACCORDING TO EN 12162

DURABILITY TEST

NOISE TEST

ACCORDING TO EN 12639 WITH:

OCTAVE BAND FREQUENCY ANALYSIS

SOUND INTENSITY DETERMINATION

“MAP” OF THE PRODUCT NOISE

VIBRATION TEST WITH:

MEASUREMENT OF OVERALL VIBRATIONS

(acceleration, speed, movement)

MEASUREMENT OFTHE PHASE OF THE VIBRATIONS

FFT ANALYSIS

MONITORING OF THE OVERALL VIBRATIONS AS A FUNCTION OF TIME AND SPEED

(BODE DIAGRAM)

WAVEFORM

INSTRUMENTSANDEQUIPMENT

Calibrated instruments for all values measured with calibration cycles in accordance with the recommendations outlined in ISO 9906

- RANGES OF CALIBRATED MOTORS

- GENERATORS FOR SUPPLYING THE REQUIRED POWER

- TWO VFDs (ONE FOR POWER OUTPUTS UP TO 300 kW AND THE OTHER FOR POWER OUTPUTS UP TO 1,500 kW) FOR THE VARIABLE SPEED TESTS

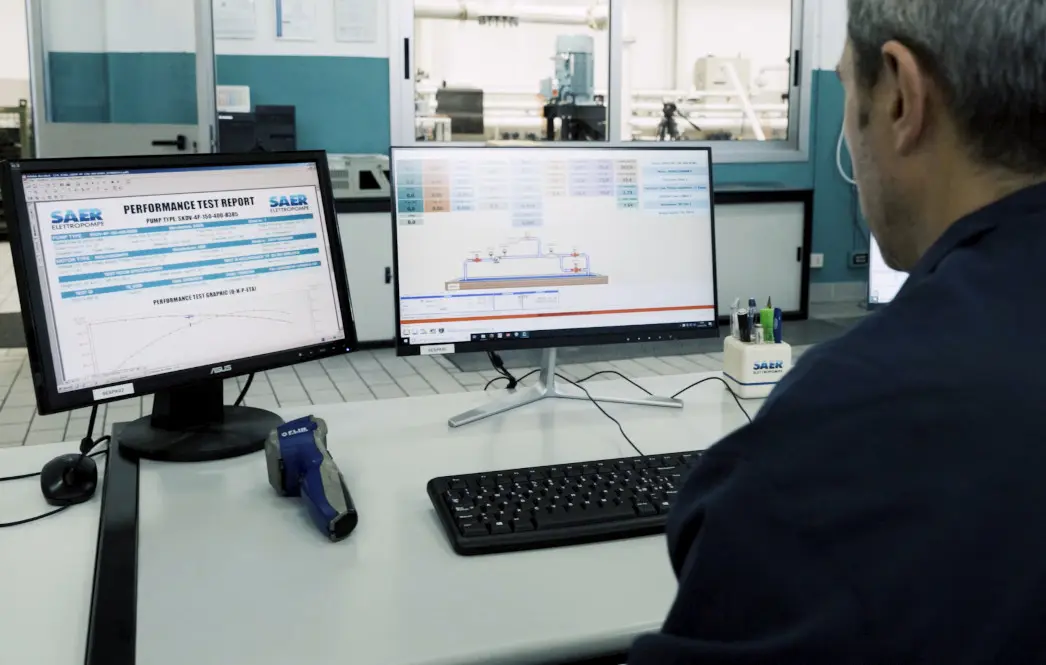

- CONTROL ROOM: NETWORKED PCs VIA WHICH DEDICATED SOFTWARE IS USED TO MONITOR THE HYDRAULIC LINES AND BRAKES FOR THE MOTORS

- SOLAR PANELS FOR TESTING OF SOLAR PUMPS

INSTRUMENTS AND

EQUIPMENT

The ultimate goal is to ensure the highest levels of safety and quality standards in accordance with applicable standards and regulations.